Services and products

What we offer

We perform professional applications of photo active nano material TiZonic

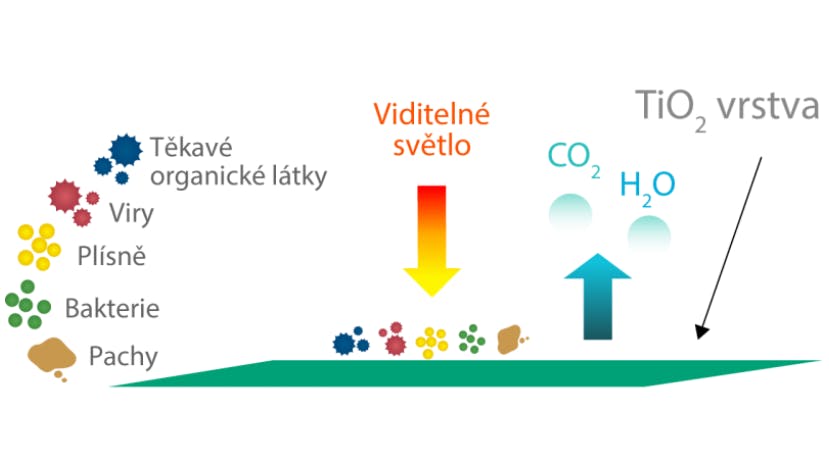

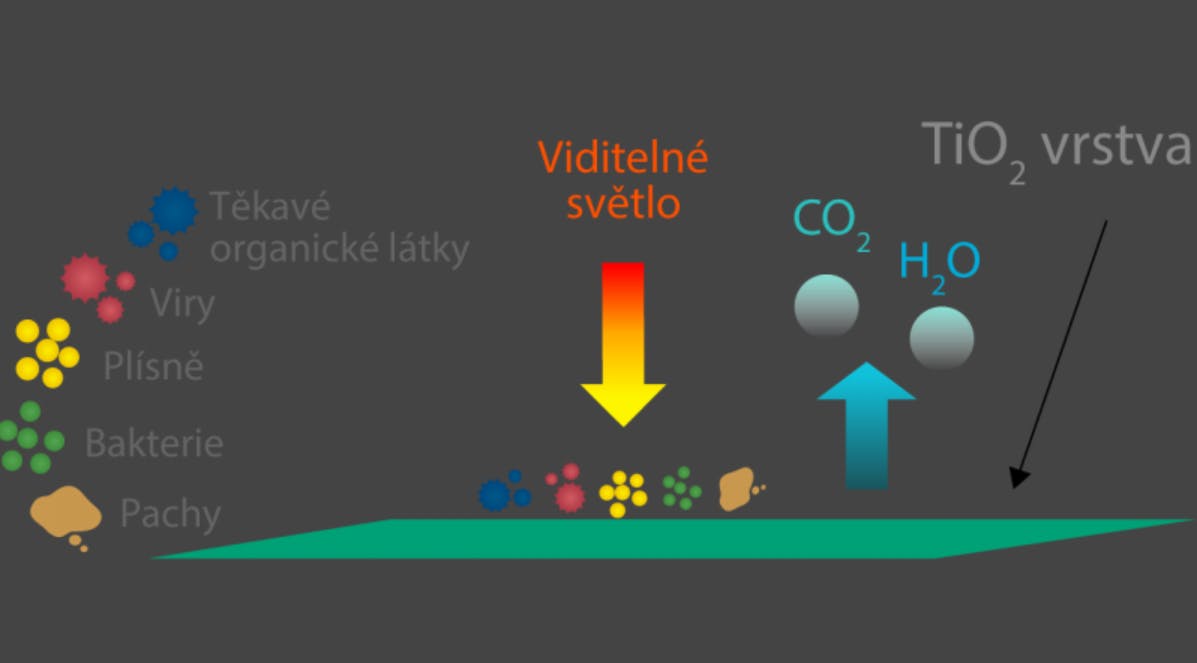

Photocalytic mineralization

The advantage of this process is that it does not produce unwanted toxic substances.

Nanotechnology applications

Using special spraying technologies, we create ultra-fine protective coatings of photoactive Nano Material TiZonic on surface surfaces. We use two types of spraying technologies for applications. ESS technology (electrostatic spraying), where thanks to electrostatics we achieve a so-called 3D effect, which in practice means 100% coverage of surface surfaces of surfaces, especially those where nano particles do not normally reach thanks to approaches without the use of this technology.

The application itself takes place with minimal traffic restrictions – it lasts in minutes. No precautions are taken before application, nothing is uncovered, it does not hide.

Features and effects of TiZonic - GUARANTEED PRODUCT

Atp

The ATP test isa POLLUTION TEST because it detects not only microbialpollution , but also the presence of organic matter ,which serves as a substrate for capturing microorganisms, is a breeding ground for their growth and at the same time their protection from the action of disinfectants.

What we offer

We offer new SAFE HYGIENIC TECHNOLOGIES for surface treatment using small TiO2 particles.

We perform professional applications of photo active nano material TiZonic - nano titanium oxide

Photocalytic mineralization

Due to photocalytic oxidation, mechanical and chemical impurities are destroyed,odors are erusted, volatile organic substances are ly emulation, and all this has been going on for many years . Substances degradable by photocalyses also include, for example, gaseous oxides, ozone (O3), ammonia, hydrogen sulphuricacid , chlorinated hydrocarbons , aromatic hydrocarbons, pesticides, microfine particles.

TiZonic nano application is a modern technology with broad-spectrum effects. The combination of nano material based on nano titanium oxide and visible light offers new, desired and necessary properties for treated surfaces.

In connection with photocacalytic mineralization, studies and information on the effects of professionally called INACTIVATION OF PATHOGENS can be found on the available servers. IT IS THE SUPPRESSION OF THE ACTIVITY OF MICROORGANISMS - THEIR NEUTRALIZATION. The nanoYo application system inactivates bacteria, viruses and parasites using a photoactive substance - TiO2 ( precisely defined parameters and morphological structure) and visible light, which is a completely new concept of protection against microorganisms, where this is not a classic chemical disinfection of surfaces, but through a photocalytic reaction, targeted and yet specific destruction of pathogen genomes occurs.

The nano material itself , which is applied to surfaces where it creates a stable kristalic grid with absolute adhesion, is not consumed and inactivation of pathogens only "mediates" as a photocalyst.

After illuminating the surfaces treated with TiZonic visible light, these surfaces show permanent antiviral and antibacterial activity even in dark conditions - without the presence of light for a certain period of time (for example, overnight).

Photocalytic cleaning of air and surfaces of surfaces.

One of the most pronounced properties of the TiO2 catalyst is its powerful destructive or decomposition effect, the essence of which is the oxidation process. In addition, titanium dioxide is capable of decomposing almost all organic compounds during light irradiation. This is because the energy provided by the photocalytic reaction is "quantum". This means that the energy of each photon is the same and does not depend on the intensity of light. Therefore, even at low light intensity, it is available for the course of chemical reactions on the surface of titanium dioxide energy, which corresponds to thermal energy at 30 000 °C. At such a high temperature, the organic substance can be instantly oxidized to CO2 and H2O. In other words, it's burned. In reality, however, the surface of titanium dioxide does not reach such a high temperature. Microbial pollutants are one of the serious sources of internal air pollution and surface surfaces. They consist of particles of biological origin (bacteria, viruses, fungi). An application that destroys floating or lying bacteria, viruses in the air and on surfaces... is relatively new. However, it has been used for at least 10 years, so we already have experience. The time determining the oxidative removal of bacterial mass from the surface can be important for the design of self-cleaning surfaces wherever, due to large accumulation and migration of humans, bacterial meat takes on dangerous proportions.

Nanotechnology applications

Due to the size of titanium nano particles, we are talking about so-called "absolute adhesion" to surfaces, and these nano particles can only be removed mechanically - by abrasion, strong abrasive influences.

The only condition for the implementation of the application is that the surfaces intended for application are clean, free of grease and dirt, dry. This can be achieved by normal cleaning

The application itself runs only with

minimal traffic restrictions and lasts in minutes.

No precautions are taken before application, nothing is uncovered, it does not hide.

The application itself runs only with

minimal traffic restrictions and lasts in minutes.

No precautions are taken before application, nothing is uncovered, it does not hide.

The 42-month-long European NANOHOUSE Project has demonstrated

that nanoparticles used in paints on the facades of houses do not pose a particular health risk.

The 42-month-long European NANOHOUSE Project has demonstrated

that nanoparticles used in paints on the facades of houses do not pose a particular health risk.

Features and effects of TiZonic

TiZonic is referred to as a 4th generation nano material

(TITANIUM COLLOID)

TiZonic is referred to as a 4th generation nano material

(TITANIUM COLLOID)

Properties of TiO-based materials2:

• High abrasion resistance, washing

• Trouble-free use up to 540°C

• Specific thermal conductivity 7/10000K

• Antistatic

• Semiconductor

• Interesting optical properties

◦extremely high light dispersion

◦better light refractive index than diamond (n = 2.4)

TiZonic was subjected to careful analysis as part of a research task carried out by MU in Brno.

TiZonic was subjected to careful analysis as part of a research task carried out by MU in Brno.

Based on the measurement of contact angles and the results obtained, it is clear that TiZonic creates so-called hydrophilic surfaces and oil-philic surfaces.

Images from SEM and TEM showed a similar structure of the TiZonic layer, when it was subsequently possible to determine the composition of kristalks from nanostructures. Images from TEM and HRTEM and subsequent diffrtograms determined that the TiZonic coating consists mainly of TiO nanoc crystals2 (anatas) and then creates these layers on the treated surfaces

This demonstrates the following effects of TiZonic:

- surfaces have high long-term stability - they are kept clean for a long time - self-cleaning

Effect

- due to the oxidative effects of photoactive titanium, long-term decomposion occurs

mechanical, chemical, organic impurities

- decompression of odors in interiors

- decompression of volatile organic substances in interiors

- elimination of risks of transmission of contact diseases, nosocomia diseases

- significant reduction of grease and dirt adhesion to surfaces, adhesion of microfine particles

thus limiting the creation of conditions for the

Microorganisms

- easier and faster maintenance and cleaning of treated areas

- due to the surface tension of nano titanium oxide, the chemical bonds of impurities to

treated surfaces

- conventional sanitation processes achieve significantly on surfaces treated with nanotitane

higher efficiency

ATP measurement

ATP Bioluminescent Method

The ATP test isa POLLUTION TEST because it detects not only microbialpollution , but also the presence of organic matter ,which serves as a substrate for capturing microorganisms, is a breeding ground for their growth and at the same time their protection from the action of disinfectants.

All organic matter (live or originally alive) contains ATP, including food, bacteria, fune and other organisms. The ATP test is an ideal method of checking the success of cleaning processes!

BIOLUMINESCENCE occurs in bacteria (and other organisms - fungi, protozoa, love birds...) – it is the emission (release) of light in living organisms. It is the result of specific biochemical reactions. Organic substances have the ability to convert absorbed energy into light = luminescent substances. Light is produced as a by-product.

Bioluminescence

found application in medicine, in space research, in the field of biological research...

Bioluminescence

There is oxidation of substrates called luciferins in the presence of oxygen. Light is produced as a by-product of luciferase catalyzed (induced) reaction, in which substrates are oxidized (the substrate is the environment in which the organism lives) called luciferins in the presence of oxygen. These reactions take place only in the presence of oxygen, and the presence of 2 substances is always necessary: luciferase and luciferin, ATP and magnesium ions.

LUCIFERIN = substances that can be a substrate for the enzyme luciferase and produce light.

LUCIFERASE = aggregate name for enzymes allowing the formation of bioluminescence.

ATP = adenosintrifosphate - occurs in all organisms - is an important source of energy for living cells.

luciferin + O2 ----------------------- oxyluciferine + CO2 + light

By oxidation, the molecule enters an excitatory state, when it returns to a state with lower energy, energy is released in the form of light.

luciferin + O2 ----------------------- oxyluciferine + CO2 + light

The bioluminescent method is used in an environment in which the hygiene of technological processes and the cleanliness of premises and equipment must be quickly detected and monitored – an accurate method for measuring sanitation efficiency.

The amount of light released can be objectively quantified using the sensitive KIKKOMAN = luminometer. This quantity is expressed in relative light units - RLU.

RLU is directly dependent on the amount of ATP in the sample and thus directly depends on the amount of biological contamination in the sample.